UDI Directive

In the future, every medical device should be uniquely labelled and identifiable worldwide. This will be done with the aid of Unique Device Identification, or UDI for short. Across Europe, the introduction of this labelling is regulated by the Medical Device Regulation (MDR). It was already introduced in 2017 and is now gradually coming into force. For the introduction and implementation, the regulation uses a risk-based approach, i.e. products in risk class III must be labelled first and products in class I last. This is intended to better ensure patient safety and the traceability and retraceability of medical devices. To this end, each product is given a product identification in the form of a numerical code and a linear or 2D barcode code. The rationality is this: The numerical code is readable by humans, the barcode by machines. If the product is very small, a machine-readable code is also sufficient. The UDI requirements are now an important part of the conformity assessment to obtain the CE marking.

Components of the UDI labelling system

The UDI system consists of a unique identification of the product, the packaging levels and the associated database entries. This increases the global traceability and identification of products. This creates better transparency in the market and ensures faster processing of corrective actions or recalls, including regulatory notifications.

UDI-DI & UDI-PI

The UDI consists of two parts: the product identifier (UDI-DI) and the production identifier (UDI-PI).

The former (UDI-DI) is used to identify the product and the manufacturer and must be applied to the product itself and additionally also to its packaging. It is assigned by the responsible allocation body and is static. Up to 20 data points are contained in the identifier, such as information on the trade name, reusability, sterility, etc. The latter (UDI-PI) marks the batch of a product, e.g. lot or batch numbers, serial numbers, expiry and/or manufacturing data and is assigned by the manufacturer itself.

Basic UDI-DI

The basic UDI-DI has a special role. It identifies similar products with the same intended purpose and risk class that differ slightly, for example in engine power. Thus, it is a kind of model identification. Although it functions as a key for the UDI database EUDAMED, it still does not appear on the product or packaging, but is specified by manufacturers with other data elements at the UDI database. Manufacturers must also maintain a list of all assigned UDIs for each medical device. This is part of the technical documentation.

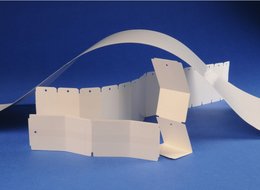

UDI on packaging

Furthermore, as of 2021, manufacturers of medical devices must not only successively mark the products themselves (depending on the class of the medical device), but also their packaging (exception: containers) with the UDI. The following applies here: The code must remain legible throughout the entire service life. This applies to all medical devices.

UDI labelling: important legal requirement, but associated with additional expense

With the UDI Directive, the EU is taking a major step forward in the area of safety for patients in the medical & pharmaceutical sector through clear labelling and complete traceability. Nevertheless, the hurdles for affected manufacturers are not without difficulty and the implementation can hardly be mastered without competent advice and an experienced partner. Our experts will therefore be happy to assist you with any questions and concerns you may have on the subject of labelling with the UDI.