Reusable is the goal

Labelling solutions for the ToGo sector

Optimal performance, maximum savings potential

Speed, process reliability and durability - ToGo packaging has to meet many demands to deliver practical solutions. Whether at a music festival, sports venue, a corporate event or in continuous use in service delivery – efficient practices place the highest demands on packaging. From drinking cups to food boxes. Logically, the labelling for individual containers must also withstand the demands of it‘s practical use. And it is even better when smart labelling solutions like our barcode and RFID labels open up possibilities that make packaging and containers even better. How can you do it? It's simple. With our ino:reuse solutions for all common ToGo applications.

Reusable to offer more climate and nature protection

The future belongs to reusable packaging. Reusable solutions are already used as a matter of course in many places in everyday (working) life. In light of our finite resources and a growing awareness of ecological issues, this will only increase in the coming years. We applaud this thinking. As label experts, we are concerned with the question of how intelligent and modern labelling solutions can make reusable packaging even better, smarter and more environmentally friendly. That's why we are forever developing our plastics, adhesives and inlays. Not only to meet current requirements, but to always be one step ahead. As an inmould variant, our ino:reuse solution is so robust that it can easily withstand up to 500 washing and cleaning cycles. And we have also thought ahead when it comes to the problem of the many different cycles that still exist today. Our ino:reuse solutions are already equipped to make it possible for all major retail partners to return and collect their packaging waste. We are ready for reuse.

ino:reUse - Our barcode and RFID solutions for ToGo packaging

Technical specifications

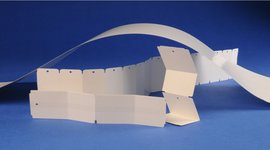

Our ino:reuse solutions for ToGo packaging are available in different variants and shapes - from "standard" to highly individual. Please contact us.

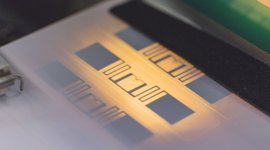

- Various adhesive or inmould versions with 2D code and/or RFID

- RFID inlay with high range and optimized radiation characteristics

- Easy application or integration into the production process

- Chips are programmable according to your requirements

The right labelling for ToGo packaging

Advantages

- post production application possible

- printing of labels in controlled production at Inotec

- printing of labels "on demand" with TTR printer on site

- laminated labels reliably protected against wear

Disadvantages

- double number risk with "on demand" label production on site

- “on demand" labels without protective laminate wear out quickly in the usage processes

Advantages

- cost savings due to insertion of the label already in the injection molding process, no second pass for label application necessary

- tamper-proof due to fusion of label with the plastic product

- permanent, secure and seamless labelling

- 100 % hygienic safety without adhesive edges

- no risk of double numbering

Disadvantages

- inmould requirements must be taken into account during production

- no "on demand" label production possible

Labels for reusable containers

Frequently asked questions

Yes. When developing our labels, we have been making sure for many years that all materials are constantly developed further so that they meet the high standards of food legislation. Our label materials and adhesives are ISEGA-certified and therefore suitable for contact with food. Our labelling solutions always meet the highest standards.

Yes, our inmould variants can be integrated into the containers using the injection moulding process so that the labels are directly connected to the packaging. This ensures extremely good hygiene and resistance of the labelling. The special feature of our ino:reuse inmould solution is that we have paid particular attention to easy and uncomplicated integration into the production process. This shortens production enormously and saves a lot of resources in logistics and process costs.

Our reusable mission

We make the future

Yes, we may "just make labels", but there's actually much more to it than that. With our labelling solutions, we always pursue the goal of optimally helping our customers with their challenges. And to make processes and workflows in many industries smarter, safer and more efficient. We have developed the best labelling solutions to help you get the best out of your packaging. And we are always continue to optimize our solutions so that we can develop 100% closed and secure cycles as quickly as possible in the future.