Permanent barcode & RFID in-mould labels for maximum security

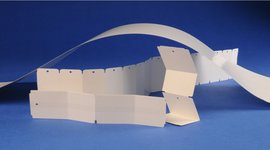

Our customised in-mould solutions enable permanent and tamper-proof labelling of plastic pallets, containers and trays in reusable applications. The label you choose is firmly integrated into the material during the injection moulding process, providing optimum protection against mechanical and chemical influences.

Whether as a barcode or RFID variant, the markings remain reliably legible even with intensive use. Regardless of exposure to abrasion, UV radiation, cleaning agents, weak acids or other chemicals. Our labels thus form the basis for secure identification, automated recording processes and complete traceability in demanding industrial and logistics environments.

Always individual. Always secure. Always inotec!

At a glance

Inmould: How our labels work

Application

Barcode in-mould:

- Integration of the label in the injection moulding process

- Permanent connection to the plastic carrier

- Consistent readability even under heavy use

- Resistant to chemicals and UV radiation

- Suitable for hygienic applications and food contact

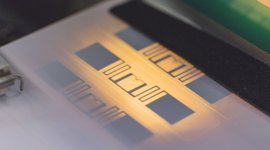

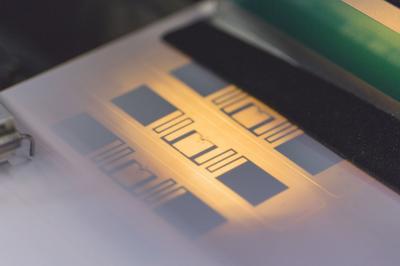

RFID in-mould:

- Combination of barcode, plain text, antenna and chip

- Contactless data capture even without line of sight

- Integrated into the container, completely tamper-proof

- Meets the highest requirements in the food and pharmaceutical industries

- GS1-certified solution for reusable and meat containers

Technologies

Barcode or RFID in-mould label

Together, we will find the right in-mould solution for your application, industry and requirements: whether classic barcode labelling or smart RFID technology, both variants are firmly integrated into the plastic, withstand even the harshest environmental conditions and ensure permanent, secure identification and traceability.

Advantages

- Extends the advantages of the inmould label with RFID functions

- 3-in-1 auto ID elements possible (barcode / plain text / RFID)

- An integral part of returnable transport packaging despite RFID technology

- Extremely robust and resistant

- Permanent inventory of returnable transport packaging possible

- Extreme durability against abrasion, chemicals, high pressure, temperature and UV radiation

- Maximum hygiene in accordance with GS1 standards for the food and pharmaceutical industries

- Process cost reduction through elimination of additional adhesive steps

- Sustainability through integration of identical, recyclable materials for an environmentally conscious material cycle

- Customised labels in variable formats, colours and coding types (barcode, QR code, RFID)

- Easy integration of logos and product information in the highest print quality

- Precise digital printing with high-resolution display for optimal labelling

- Material diversity thanks to compatibility with PE, PP, ABS, PS, nylon and polycarbonate

Applications & examples

In-mould markings in a concrete environment

Our in-mould solutions are always manufactured to meet specific requirements. From research and development to manufacturing and installation, training and long-term service, we take care of everything and can therefore serve numerous industries.