Containers, pallets, trays: for more than 70 years, companies worldwide have placed their trust in the durable and versatile products of Georg Utz GmbH. Time and again, inotec has supplied suitable labelling solutions for this purpose. When a durable and Auto-ID-compatible label was needed for a new reusable standard box, the two companies joined forces once again. Together with GS1, they created the GS1 SMART-Box – a product that is already setting standards for the circular economy of the future shortly after its market launch.

Case study: RFID in-mould label for the GS1 SMART box from Georg Utz GmbH

The starting point

Reusable packaging is the future. That is why companies from industry and trade agreed some time ago on a new, common container standard for the supply chain between production and central warehouses. In order to be able to use the standardised box in a wide variety of environments and circulation systems, a durable, resistant labelling solution was sought that would combine all auto-ID elements (barcode, 2D code, RFID) on a single label, thus enabling efficient traceability. The customer wanted the labelling to be integrated directly into the container during production, to meet hygiene requirements and to enable bulk and contactless reading.

The inotec solution

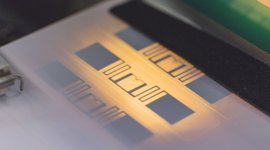

Applications such as the GS1 SMART Box are perfect for RFID in-mould labels from inotec. The label contains a barcode, an integrated RFID antenna and an RFID chip, and is inseparably connected to the container. This not only guarantees permanent labelling, but also takes the circular economy to a new level thanks to the multiple readout options. Bulk readout, which is made possible by RFID technology, greatly simplifies logistics, reduces errors and streamlines processes. RFID also enables seamless traceability, absolute tamper-proofing and fast, efficient data transfer at all times (track & trace). Thanks to extensive product testing, during which various technical parameters were fine-tuned, and the combination of in-mould and RFID, inotec was able to meet all of Utz's requirements 100% with the label it supplied. And the result not only convinced the customer: the label for the GS1 SMART box won the award for the best product in the ‘Identification, Packaging and Loading Technology’ category at LogiMAT 2021.

Label qualification

Robust, secure, versatile: the RFID in-mould label from inotec is what makes the GS1 SMART-Box truly smart. And not just because of the combination of barcode, 2D code and RFID technology, which sets new standards in terms of unique identification.

In-mould labels from inotec have an integrated chip that is inserted directly during container production and fused with it. The injection moulding process makes the label an integral part of the reusable load carrier and absolutely tamper-proof. The in-mould labels are flush with the surface, cannot fall off, are waterproof, chemical and UV resistant, and extremely robust against mechanical influences. Precisely because of its indissoluble connection to the load carrier, the label is perfectly suited for sustainable recycling systems in industry and logistics.

inotec RFID in-mould labels are delivered in stacks and can be easily and efficiently integrated into the customer's production process. Thanks to various antenna and chip types and numerous design options, there is a suitable label variant for every application.

Quote from Jochen Wessels, Sales Manager and Authorised Signatory at Georg Utz GmbH

“inotec has been a reliable and innovative partner of Georg Utz GmbH for many years. The GS1 SMART-Box project is of the utmost importance to us, so it was clear to us that we wanted inotec at our side as a trusted partner here too. The inotec RFID Inmould Label is a smart solution which, in combination with the GS1 SMART-Box, sets new standards as a packaging concept.”

Your Contact

Stefan Meyer

Technical Sales Director

04321-87 09-38

meyer[at]inotec.de